Although mass produced products have been in the market since the early 1900s, many new businesses shun away from the idea. In the age of customization, the market for these mass-produced items seems to have decreased. However, this is not the case.

A glance at the statistics of the global manufacturing industry says a lot about mass-produced products. In 2023, the value added in the current manufacturing industry is an estimated $14.83 trillion US dollars. Both automobiles and materials are mass-produced items.

In this blog, we will cover all the information you need to understand the concept of mass production. Moreover, we will also include the pros and cons, steps, and where to find suppliers for your mass production.

- Chapter 1: Overview of Mass Produced Goods

- Chapter 2: 7 Steps to Mass Produce Products in China

- 1) Understand your Needs and Requirements

- 2) Find Which Type of Manufacturer You Would Want to Go with

- 3) Do In-depth Research on the Manufacturer

- 4) Formulation of the Product Design

- 5) Approach the Manufacturer with a Complete BOM – Bill of Materials

- 6) Start with the Prototype Development

- 7) Launch the Prototype in the Market – Check Feedback

- 8) Incorporate Feedback and Changes in the Prototype If Required

- 9) Sign the Contract with the Manufacturer

- 10) Carry Out Mass Production when Satisfied

- Chapter 3: 5 Characteristics of Mass Produced Goods

- Chapter 4: Advantages and Disadvantages of Mass Produced Goods

- Chapter 5: 4 Steps to Find a Chinese Manufacturer for Your Mass Produced Goods

- Chapter 6: FAQs Regarding Mass Produced Goods

- Conclusion

Chapter 1: Overview of Mass Produced Goods

For the past few years, buyers and sellers have focused on customization. It is assumed that customized products are the best and they are the only ones that are in demand. However, this is not the case. Mass-produced goods have their own market. For instance, canned food, soaps, detergents, medicines, and other household items and appliances.

In this chapter, we will give an overview of what mass-produced items are.

1) What is Mass Production?

Mass production means the manufacturing of a standard product that continues for a long time. The sheer volume of mass-produced items is so large that the manufacturing of these products mostly uses automated production lines.

Moreover, these automated lines ensure uniformity of design and help the products remain standard.

These products are moved from one production to the other production lines as these lines are specialized to perform certain features. For instance, when Coca-Cola bottles are filled, they keep moving along the assembly line.

They might be filled at one point and capped at the other. While they are being capped, new bottles are placed on the assembly line to be filled. Thus, there is process continuity and the bottles keep filling and capping throughout.

2) Who are the Pioneers of Mass Production?

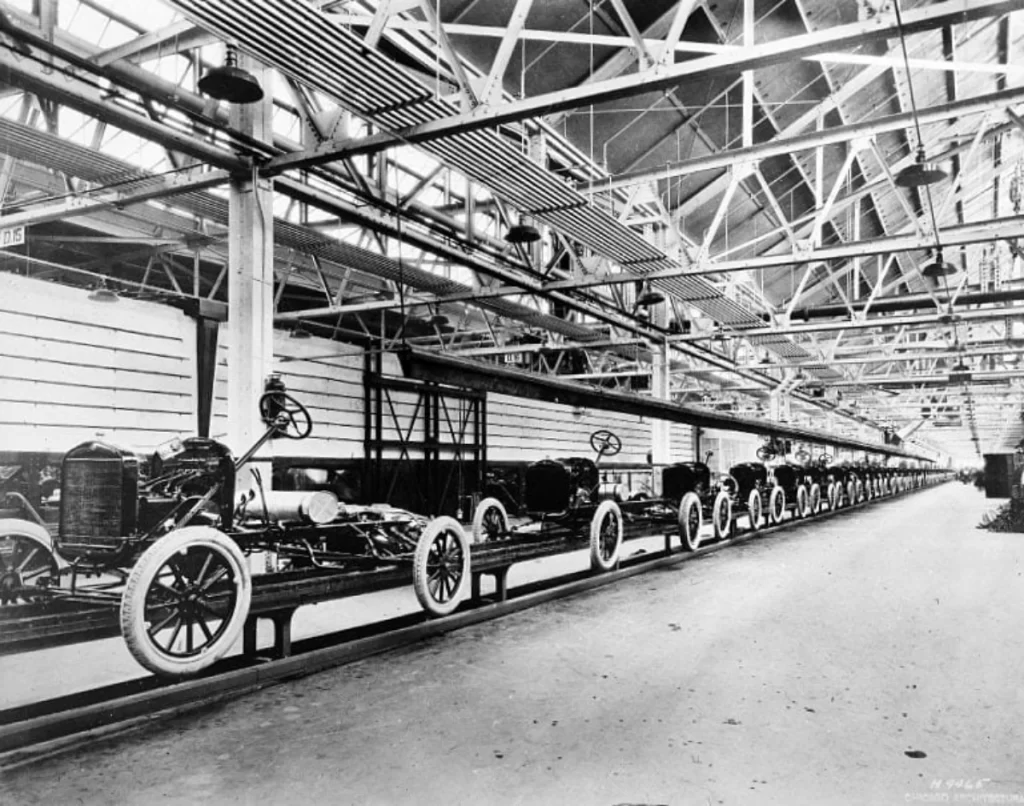

Undoubtedly, the pioneers of modern mass production are Henry Ford and his colleagues. The first moving-belt conveyor was established in 1913 by the Ford Motor Company.

This greatly reduced the production time from 18 minutes to 5 minutes per magneto, which is amazing!

From here, there was no turning back! The production technique was then applied to the automobile body and then car assembly. Furthermore, the production line design allows optimum work division along with speed, accuracy, work height and synchronization of similar operations.

Once word was out about Ford’s operations, the world was quick to adopt this production method. This led to a huge increase in the manufacturing capacity of the world.

3) Mass Customization VS Mass Production

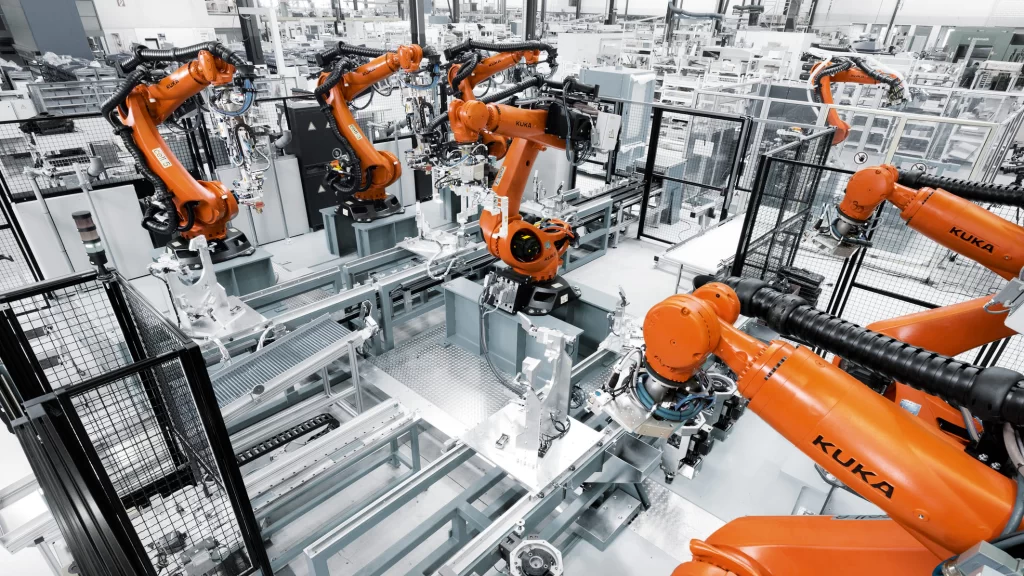

Mass production is the production of a high volume of standardized products. Moreover, these products are manufactured on specialized assembly lines by robotic machines. However, human labour is also used when required.

On the other hand, mass customization can be thought of as a step ahead of mass production. Rather than producing standardized products on a large scale, mass customization produces customized products on a large scale.

Mass customization combines both the efficiencies of mass production and the ability to customize products. Thus, customized products are produced at lower costs. Mostly, automatic machines and computer software are used to customize products in this case.

4) What Goods can be Mass Produced?

Technically, any item can be mass produced. Nevertheless, the major mass produced items include automobiles, mobile phones, canned goods, shoes, clothes, household appliances, consumer goods like soaps, dishwashing liquid, detergent etc.LoreIf you look closely, the market is full of mass produced items that we use daily.

If you look closely, the market is full of mass produced items that we use daily.

5) How does Mass Production Work?

In mass production, there are many assembly lines where there are people who do specific tasks. For instance, if the machines are pouring liquid into a bottle, there will be people/machines on the conveyor who will be putting on caps. Next, there might be people who are putting labels on the bottles etc.

In short, in mass production, identical operations are carried out on the products manufactured.

6) Costs Associated with Mass Production

Even though mass production is cheap as you can achieve economies of scale in it, there are still some costs associated with it. Firstly, you need to pay for labour. Secondly, there are raw materials and thirdly, the major costs are overhead costs. Once you are done with all direct and indirect costs, you can add them up.

The final cost of mass produced products is gained by adding up all the goods. However, the total cost of production of mass produced goods is calculated by dividing the overall cost by the number of units produced.

Chapter 2: 7 Steps to Mass Produce Products in China

Now that you know what are mass-produced products, it is time to understand the production process for them. On paper, it seems easy. All you need to do is find the right China manufacturer and you are good to go! However, it is not so easy.

So, let’s take a look at the 7 steps that go into making mass-produced goods.

1) Understand your Needs and Requirements

You never enter the business world with a virgin mind. For instance, you just don’t wake up one day and decide to do a business. Moreover, you never just start typing in “Chinese suppliers and manufacturers” and start contacting all of them left and right.

When you think of starting a business, you already have a vague idea of what you are looking for. Maybe you want to go into the apparel industry. Or, the electronics industry appeals to you.

Whatever the case is, you have a rough idea of what product you want to sell or which business you want to start.

2) Find Which Type of Manufacturer You Would Want to Go with

Now, you have two options to go by. Firstly, you need to check if you want to come up with a new product which does not already exist in the market. Secondly, you can go for a product that already has a market demand and presence.

Once you have made the choice, you have to select which manufacturer you want to with. For new products, choose an OEM manufacturer. For already existing products, an ODM manufacturer will be the right choice.

Read all about ODM and OEM manufacturers in this blog here.

3) Do In-depth Research on the Manufacturer

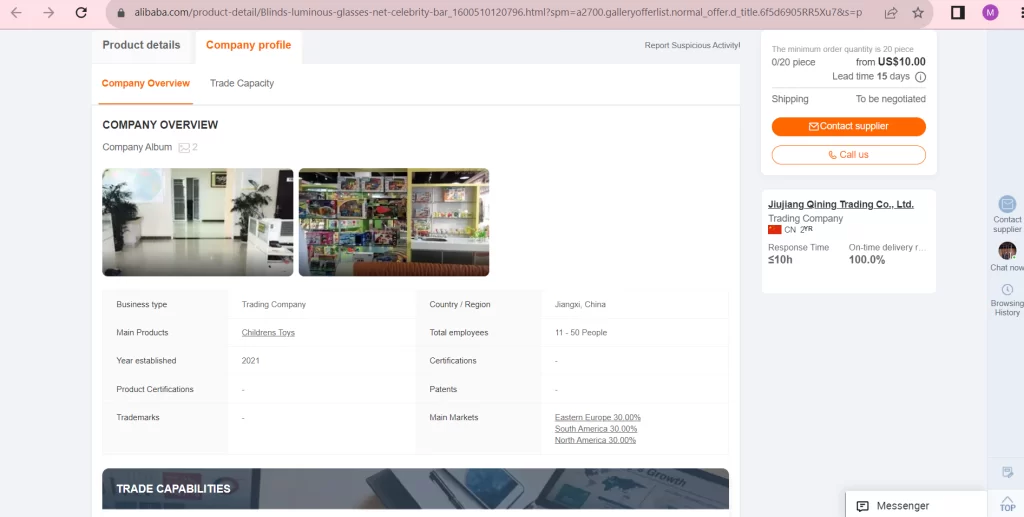

Once you have selected which type of manufacturer/supplier you are going to go for, it is time to select the supplier. There are many ways in which you can look for suppliers. Firstly, you can look at different online forums, social media and Chinese wholesale websites. These are excellent platforms where hundreds and thousands of suppliers get together to find buyers.

Undoubtedly, it is best to work with manufacturers when you want to deal with mass produced items. Working with trading companies for mass production can be tricky. Read our guide on how to verify whether a supplier is a manufacturer or not.

If it is still not clear to you, you can contact our sourcing agent. She is here to help and guide you in your sourcing process. So, book your free appointment with her today and get down to sourcing!

4) Formulation of the Product Design

Do you already have a product in mind? Or, do you already have a product which you want to mass produce? If yes, you might have just hit the lottery. All you need to do is skip to step 5.

However, there is a great chance that you want to bring something new to the market and work on a product design.

First things first, you will need to work with a professional designer to get everything right. First, you can give the designer an idea about what you want. Once the requirements are clear, the designer will start working and come up with a 3D product design.

Remember, if you don’t want to hire a product designer or are unsure of one, you can always contact a sourcing agent like AsianDavinci. They can help you in your new product development phase.

Just keep your eyes open for the 4 traps that a sourcing agent can get you in!

5) Approach the Manufacturer with a Complete BOM – Bill of Materials

Once you are satisfied with your product design, it is time to put things into motion. You will approach the manufacturer of your choice with a complete bill of materials. This states all the things that you will require for your mass produced items.

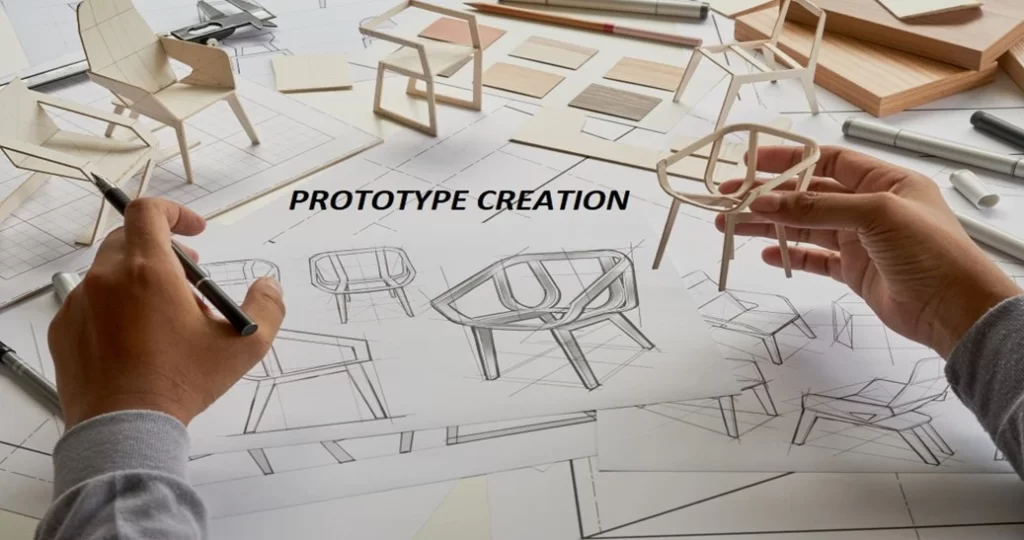

6) Start with the Prototype Development

When the manufacturer understands all your requirements and design, it is time to move forward with prototype development. Here, you can either get the prototype made by the manufacturer or someone else.

When it comes to mass produced goods, prototype development is crucial. You can spot all the problems beforehand.

7) Launch the Prototype in the Market – Check Feedback

Do you know what is the purpose of making a prototype? It is dual-purpose. Firstly, you can spot any errors in the product design and can work on it to improve it. Secondly, you can check how the product does in the market.

Generally, products don’t make it huge on the first day of sales. You need to collect all the feedback you get about the product. This will help you make any changes and save thousands of dollars before you mass produce goods.

8) Incorporate Feedback and Changes in the Prototype If Required

How did the product do in the market? Whatever feedback out get, it can be used to refine and make the product better. Moreover, you can gain valuable insight by collecting and analyzing all the details.

For example, you might see that the product did very well at one retail store you placed it at. However, the same product did not do well in the other retail stores. The trick is to gather information through surveys to see what went wrong.

There is a chance that there is nothing wrong with the product. Maybe the retail store you placed it at did not have enough clientage in the first place. Thus, sales did not happen. This feedback is also important as it will guide you about product placement.

9) Sign the Contract with the Manufacturer

After incorporating the feedback, polishing the product and making it better, it is time to sign the final contract with the manufacturer. The contract is one of the most important documents in any business deal. Therefore, it should be understood and agreed upon by both the parties.

Once you sign the contract, you are legally bound to obey it. Otherwise, there will be legal repercussions. Hence, you must understand the contract. Make it precise but detailed.

10) Carry Out Mass Production when Satisfied

After signing the contract, it is time to get started on your mass produced goods. Again, this might seem a very simple step, however, it is important to calculate how many items you want to produce carefully.

Chapter 3: 5 Characteristics of Mass Produced Goods

Some characteristics are unique for mass produced goods. Understanding them will give you a good picture of what mass produced goods look like.

1) Huge Amount of Goods Produced

Mass production can’t occur with just a few items. Just as the name suggests, mass produced goods are made in hundreds of thousands of millions. Depending on the type of product, a huge number of mass produced goods can be made in a very short time.

2) Homogenous Products

Mass produced goods are always homogenous. Mass production can occur when the same kind of product is being manufactured. These products are similar in shape, size, type, look and everything.

On the other hand, to make different types of products you require a different production line. For instance, even if you have to change the color, you will require a different production line.

3) Sequenced Work Processes

Another major characteristic of mass produced goods is that all of them go through a proper sequence of work processes. There is a flow that is fixed. For instance, if you are filling bottles, the first step on the line will be to fill the bottles. Next, the bottles will be capped. Third, the bottles will be labelled and so on.

4) Use of Machines

As the processes are sequenced and repetitive, you will see the use of machines in the production of mass produced items. The major reason for this is that machines work faster, accurately and with zero burnout.

5) Minimum Administration

Obviously, when most of the processes are done by machines, the production process requires minimum supervision and administration.

By rule of thumb, the more advanced machines the manufacturer uses, the lesser supervision will be required.

Chapter 4: Advantages and Disadvantages of Mass Produced Goods

To give a clear picture to our readers, we will include a list of both advantages and disadvantages of mass produced goods. However, it is to be noted here that the advantages outweigh the disadvantages by a great margin.

Advantages of Mass Produced Goods

a. Low Cost of Production

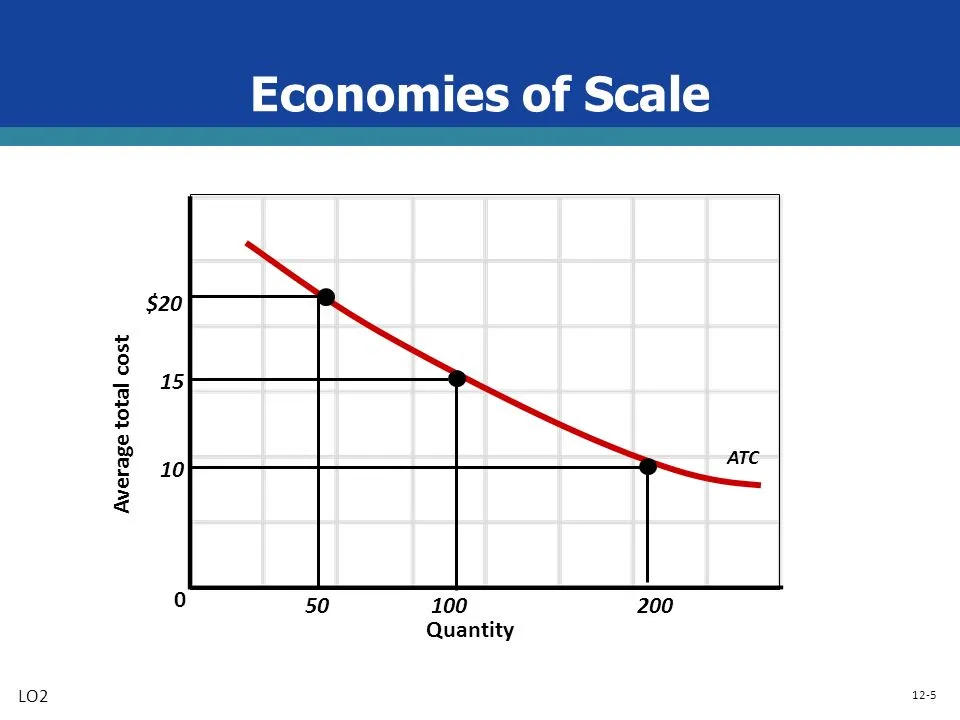

The biggest advantage that mass produced goods has is that the cost of production is low. As the goods are produced in the hundreds and thousands, the cost per unit decreases significantly.

For example, if a manufacturer is producing 100 items, the cost of production will be divided by 100 units. On the other hand, if the same manufacturer is producing 1000 items, that cost will be divided by 1000 units. Therefore, the total cost will be lower.

This is where the concept of economies of scale comes in.

Secondly, as the processes are mostly done by machines, there is less labour required. Also, there is less margin for error and defective products. That also leads to a decrease in cost.

b. Production Accuracy is Much Better

As already mentioned, most of the repetitive processes of mass produced goods are done by machines. Therefore, the production accuracy is much better. The reason for this is simple:

People tend to make mistakes; machines don’t!

Hence, the accuracy of mass produced goods is high. Each product is identical to the other.

c. There is Consistent Product Quality and Less Chance of Discrepancies

A characteristic of mass produced goods is that they are identical to each other. Thus, the quality is consistent.

Remember, by consistent quality, we don’t mean high quality. Nevertheless, all the products will be the same regardless of how they are!

Moreover, the use of machines ensures that there is a slim chance of any discrepancies. All the products are going to be uniform and the same!

d. Cheaper Raw Materials as they Are Brought in Bulk

In the process of mass production, there is a chance that you can get cheaper raw materials. This is because you will be buying in bulk for manufacturing many products. Hence, bulk buying will allow you to get amazing prices.

Read about the “7 Steps to Buy in Bulk from China: Tip and Strategies 2023” to get an idea of how to buy in bulk!

d. Higher Efficiency Levels

With mass production, you can reach higher efficiency levels quicker. For instance, if you produce 1000 items individually, it will take you months. Even if you break down 1000 items into groups of 100 or 250, it is going to take days to produce them. Meanwhile, producing 1000 items at once, in the same place is not going to take that much time.

If you choose the right manufacturer, you can even produce these 1000 items in a day or 2. Hence, with mass production, you can cut down on time, effort and money.

Disadvantages of Mass Produced Goods

a. It is Very Capital Intensive Leading to Higher First Investment

Mass production might help you reach economies of scale in the long run, however, it will not happen overnight. For mass produced items, the initial investment is very high. The manufacturer will be buying raw materials in bulk from their pocket.

Undoubtedly, large-scale production is going to be heavy on the pockets of small and medium businesses. Not only this, but it is also going to financially hit the manufacturer hard! So, be prepared for that first investment.

b. You Might Face Lower Employee Morale

When things become repetitive, people tend to lose their interest in the work. Thus, leading to a decrease in employee morale. This is just what happens in mass produced goods. When processes become monotonous, repetitive and predictable, work becomes boring.

Moreover, in mass production, most of the work is done by machines. The manufacturer can end up losing the interest of the employees.

c. You can Make a Limited number of Mass Produced Goods at a Time

The drawback of mass production is that there is just one product that can be made on the assembly line. Product differentiation or product expansion is not possible. For that, you will be requiring dedicated assembly lines.

d. Mass Production Recalls in Case Any Issue Occurs

What happens if there is a defect in even one of your mass produced items? This is the worst nightmare of any manufacturer/business. The sheer number of items produced during mass production is huge. If there is a defect in one, there is a 99% chance that there are defects in the others.

When this happens, all the production needs to be recalled. This can mean a loss of thousands or millions to the business.

Did reading all these disadvantages confuse you whether to go ahead with making mass produced goods or not? Don’t worry – we have you covered. Book a free consultation with our sourcing agent today and see how she can help you further.

Chapter 5: 4 Steps to Find a Chinese Manufacturer for Your Mass Produced Goods

Understanding how to manufacture mass produced items was just one step. The well-being and quality of the mass-produced items depend largely on the manufacturer you choose for the business. Therefore, it is important to choose wisely. In this chapter, we briefly discuss the 4 major ways in which you can find a Chinese manufacturer for yourself.

1) Online Sources like Websites, Internet and Social Media

Initial research, whatever topic it might be related to, should be conducted online. Undoubtedly, everyone does not have the time or resources to travel directly to China to start looking for suppliers. The most practical way is to search on wholesale websites.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Once you have selected a manufacturer, you go ahead to check and cross-check them on different social media platforms.

2) Trade Fairs Held in China

China is the home to some of the world’s largest trade fairs and exhibitions. These are mostly held annually, bi-annually or once every 2 years.

The world’s largest and oldest Fair, the Canton Fair 2023 is taking place just as you read this article!

As these fairs see a global audience, the Chinese management goes out of their way to cater to them. Check out this video on the practical logistics that the Canton Fair has to offer.

Attending these trade fairs is a once-in-a-lifetime opportunity for many. So, you should know what preparations to make before attending one. Check out all the details in this video here.

Check out the top 10 fairs that you must attend in China here.

3) Referrals Through Reliable People

If you want to be 100% sure that you are dealing with a reliable supplier/manufacturer, you should try to go for referrals. There are many people already working in the industry. Before going ahead and starting with the search process, it is a good idea to contact your peers, friends, colleagues and other people you trust.

Remember, the person referring you to the manufacturer should be trustworthy. Even then, you should do your own background checks and homework on the manufacturer you selected for your mass produced goods.

Chapter 6: FAQs Regarding Mass Produced Goods

Conclusion

Nowadays, mass produced items are back in rage! This blog covers everything you need to know about mass produced items. Not only this, we went a step further and discussed the process in detail. Understandably, the sourcing side of the business is not for everyone. This is why we, at AsianDavinci , provide sourcing services globally for a minimum fee.

You can contact us today and discuss your sourcing needs with us. We have customised plans for customers as we believe each customer is different from the rest!